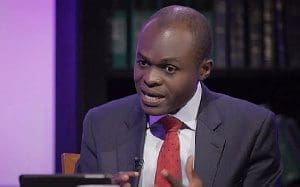

Private legal practitioner Martin Kpebu has called for increased value addition in Ghana’s cocoa sector as a way of creating more jobs, arguing that exporting raw beans enriches other countries’ economies at Ghana’s expense.

Kpebu emphasized that Ghana should process more cocoa locally rather than shipping raw beans abroad for processing into chocolate and other products. His comments highlight a longstanding debate about how Ghana can capture more value from its position as the world’s second largest cocoa producer.

“Let’s add value, process the cocoa here,” Kpebu stated, pointing to the massive economic opportunities Ghana misses by exporting primarily unprocessed beans while importing finished chocolate products at much higher prices.

The economics of cocoa value addition are compelling. Around 80% of the global cocoa industry’s annual wealth of between $130 billion and $150 billion is generated during secondary processing, including cocoa paste manufacturing, cocoa butter production, and chocolate making. Ghana currently captures only a tiny fraction of this value.

Ghana exports approximately 70% to 80% of its cocoa as raw beans. While the country has some processing capacity through companies like Cargill Ghana and Barry Callebaut, most processing happens in Europe and North America, where the bulk of value creation occurs.

The price differential tells the story clearly. Ghana receives around $3,625 per tonne for raw cocoa beans at current farmgate prices. However, processed cocoa products like cocoa butter can fetch $8,000 to $10,000 per tonne, while finished chocolate products command exponentially higher prices in retail markets.

This means that for every tonne of raw beans Ghana exports, it forgoes thousands of dollars in potential revenue that could support jobs, pay taxes, and drive economic development. European countries with no cocoa farms earn billions annually from processing and selling chocolate made from African beans.

Kpebu’s argument resonates with broader calls for African countries to move up the value chain in commodity exports. The continent produces most of the world’s cocoa, coffee, and many minerals, yet captures minimal value because processing happens elsewhere.

Ghana has made some progress on cocoa processing. The country now processes about 20% to 30% of its production domestically, up from virtually nothing decades ago. The government has implemented policies to encourage local processing, including tax incentives and guaranteed bean supplies for processors.

However, significant challenges remain. Processing cocoa requires substantial capital investment in machinery and facilities. Energy costs in Ghana are relatively high, affecting competitiveness. Access to finance for industrial projects can be difficult, and technical expertise in advanced processing remains limited.

Additionally, global chocolate manufacturers have established supply chains and processing facilities elsewhere, creating barriers to entry for Ghanaian processors trying to compete. Brand recognition and market access present further hurdles for Ghanaian chocolate products trying to penetrate international markets.

The job creation potential is substantial. Processing cocoa locally would create employment not just in factories but across the entire value chain, including packaging, logistics, quality control, marketing, and distribution. These would be higher paying, more skilled jobs than primary cocoa farming.

Some Ghanaian companies have attempted to build local chocolate brands with varying success. Products like Niche Cocoa and Golden Tree Chocolate have gained some traction, but competing with established global brands like Cadbury, Nestlé, and Lindt requires significant investment in quality, marketing, and distribution.

The government’s role is crucial. Beyond tax incentives, authorities could invest in shared processing infrastructure, provide targeted financing for cocoa processing businesses, support research and development for product innovation, and negotiate market access agreements with trading partners.

Energy sector reforms that reduce electricity costs would significantly improve the competitiveness of local processing. Reliable power supply is essential for industrial operations, and Ghana’s periodic power challenges have deterred some investors.

Education and training programs to develop local expertise in food processing, quality control, and chocolate manufacturing could help build the human capital needed for a thriving processing sector. Partnerships with international chocolate schools and training institutions could accelerate knowledge transfer.

Kpebu’s call reflects growing impatience with Ghana’s continued reliance on exporting raw materials despite decades of talk about industrialization and value addition. The question is whether political will, private sector investment, and enabling policies can finally align to transform the cocoa sector.

The recent price increases for cocoa farmers, while welcome, do not address the fundamental issue of value capture. Ghana can pay farmers better prices and still lose out on billions in potential revenue by shipping raw beans abroad for others to process and profit from.

For Kpebu and other advocates of industrialization, the path forward is clear: invest aggressively in processing capacity, develop local chocolate brands, support entrepreneurs in the sector, and gradually shift from being a raw material supplier to becoming a major player in the global processed cocoa and chocolate market.